After mergers or acquisitions, factories can often be repurposed. However, new needs and demands usually entail drastic changes in factory logistics and, in particular, the flow of people and materials. With dynamic simulation, different scenarios can be compared and assessed virtually and fundamentally in the Site Master Planning - long before the costly experience of reality needs to rear its head.

Factory planning

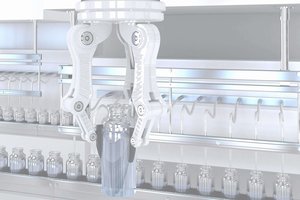

Overriding circumstances within the life sciences industry are changing rapidly. Mergers & acquisitions, technical innovations, increasing regulatory requirements. With integrated and effective factory planning, you can react flexibly to changes to ensure efficient production.

Chemgineering assists you in planning your GMP compliant factory. All requirements for laboratories, production areas, critical auxiliary systems, warehouses and infrastructure facilities are analyzed and documented in well-planned steps. We employ an interdisciplinary team to develop different variants and assess them in simulations of your production process.

Production adjustments

New market and marketing requirements trigger changes and adjustments in the production program. The technical and financial assessment of the feasibility of carrying out conversions and upgrades at existing locations and in existing infrastructures is thus a central task of factory planning.

Relocation

The ability of manufacturing sites to satisfy global demand, facilitated by reduced trade barriers and new tax incentives, impacts on production concepts, batch sizes, supply chains and warehousing capacity. Factory planning can satisfy these requirements in a timely and flexible manner

Altered sterility requirements

New forms of administration (e.g. parenteral sustained release applications), but also new production methods (e.g. cell culture fermentations) require higher quality sterile conditions both with the production of active pharmaceutical ingredients (API) as well as in the final form production. The implementation of the sterility requirements to ensure an effective avoidance of contamination must - apart from the process management itself - also already be integrated within the process architecture.

Chemgineering plans your GxP compliant factory:

- Factory planning

- Investment assessment

- Site Master Planning

- Production simulation

- Process architecture

- Zone concepts

- Feasibility study

Other topics

This website uses cookies to provide you with the best possible experience. If you continue to browse our site, you consent to our use of cookies and to our privacy policy.